Greases: Essential Lubricants for Long-Lasting Equipment Performance

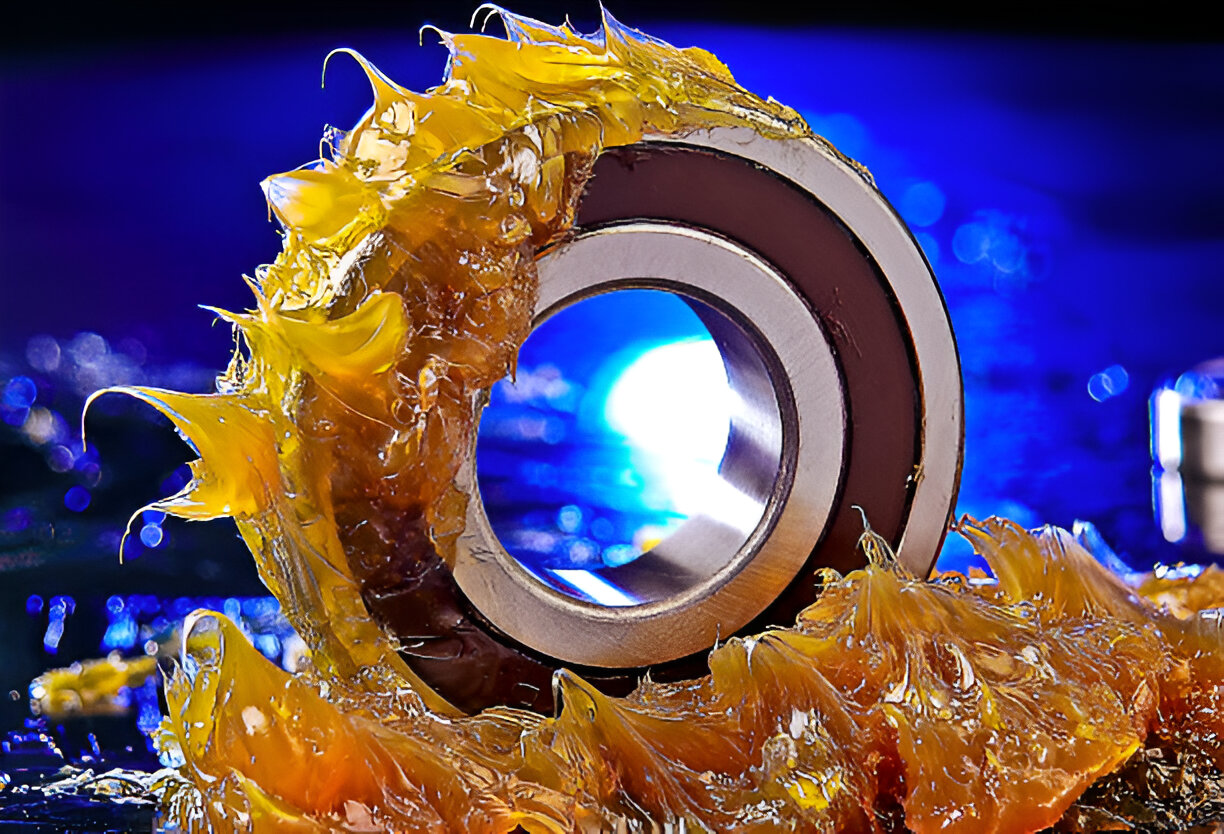

Greases are thick, semi-solid lubricants that play a critical role in maintaining and enhancing the performance of machinery and equipment across various industries. Unlike liquid oils, greases have a gel-like consistency that makes them ideal for applications where continuous lubrication is required over a prolonged period, particularly in high-pressure and high-temperature environments. Their ability to stay in place without leaking or evaporating makes greases essential for ensuring equipment reliability and longevity.

What is Grease?

Grease is a combination of a lubricating fluid (typically mineral oil, synthetic oil, or vegetable oil), a thickening agent (such as soap or complex metallic substances), and various performance-enhancing additives. The thickening agent gives grease its characteristic semi-solid consistency, allowing it to stay in place and create a protective barrier between moving parts.

There are many types of greases, each formulated for specific applications and conditions. The choice of grease depends on factors like operating temperature, pressure, load, and the type of material being lubricated.

Functions of Grease

Greases perform several essential functions in industrial applications:

- Lubrication: The primary purpose of grease is to reduce friction between moving parts, ensuring smooth operation. It forms a lubricating film that prevents metal-to-metal contact, minimizing wear and tear on equipment components.

- Sealing: Grease acts as a sealant in certain applications, keeping out dust, dirt, moisture, and other contaminants that can cause corrosion or mechanical damage. This sealing capability is especially useful in harsh environments where equipment is exposed to the elements.

- Protection Against Corrosion: Many types of greases contain anti-corrosion additives that protect metal surfaces from rust and corrosion. This is particularly important for equipment operating in wet or humid environments, such as marine or agricultural machinery.

- Temperature Management: Grease helps dissipate heat generated by friction in mechanical systems, reducing the risk of overheating. Certain high-temperature greases are designed to maintain their effectiveness even in extreme heat, ensuring reliable performance in demanding conditions.

- Shock Absorption: Grease provides a cushioning effect that helps absorb shocks and vibrations in machinery. This is particularly beneficial for equipment subjected to heavy loads, such as bearings, gears, and chassis components in construction or mining vehicles.

Types of Grease

Different types of greases are available for various industrial applications:

- Lithium Grease: One of the most commonly used greases, lithium grease is versatile and offers excellent performance in high-pressure and high-temperature environments. It has good water resistance and is suitable for applications such as automotive bearings, machinery, and industrial equipment.

- Calcium Grease: Calcium-based greases are known for their water resistance, making them ideal for marine and underwater applications. They also have good corrosion resistance but are not as effective in high-temperature conditions.

- Polyurea Grease: Polyurea greases are non-soap thickened and offer exceptional high-temperature stability. They are widely used in electric motor bearings, offering long-lasting lubrication in extreme conditions.

- Molybdenum Disulfide (Moly) Grease: Moly grease contains molybdenum disulfide as an additive, which provides enhanced protection against wear in heavy-duty applications. It is commonly used in construction equipment, heavy machinery, and automotive joints.

- Silicone Grease: Silicone grease is excellent for high-temperature applications and provides long-lasting lubrication without drying out. It is commonly used in seals, gaskets, and electrical components.

Applications of Grease

Greases are used across a wide range of industries and applications:

- Automotive Industry: Grease is widely used in the automotive industry to lubricate wheel bearings, chassis components, and suspension systems. Its ability to withstand high pressures and temperatures makes it ideal for maintaining vehicle performance.

- Industrial Machinery: In industrial settings, greases are used to lubricate bearings, gears, and other moving parts of machinery that operate under heavy loads. Their thick consistency ensures that they stay in place, providing long-lasting lubrication.

- Construction Equipment: Heavy-duty construction equipment such as bulldozers, excavators, and cranes rely on grease to protect components from extreme pressure and dirt. Greases used in these applications must offer excellent shock absorption and sealing properties.

- Agriculture: Greases play a vital role in keeping agricultural machinery, such as tractors and harvesters, running smoothly in challenging conditions like mud, dust, and moisture. Water-resistant greases are often preferred for such applications.

- Marine Industry: In marine applications, grease is used to protect boat and ship components from saltwater corrosion. Special marine greases are designed to withstand wet conditions and resist washout, ensuring the longevity of marine equipment.

Benefits of Using High-Quality Grease

Using high-quality grease offers numerous benefits, including:

- Extended Equipment Life: By reducing friction and wear, grease helps extend the life of mechanical components, reducing the need for frequent repairs or replacements.

- Improved Efficiency: Proper lubrication provided by grease ensures that machinery operates smoothly and efficiently, reducing energy consumption and operational costs.

- Reduced Downtime: Well-lubricated equipment experiences fewer breakdowns, leading to less downtime and improved productivity.

- Protection in Harsh Conditions: Grease provides excellent protection against water, dust, and other contaminants, making it ideal for use in harsh or extreme environments.

- Cost Savings: The long-lasting performance of grease reduces the frequency of lubrication intervals, resulting in cost savings over time.

Conclusion

Greases are essential for the reliable operation of equipment across various industries, providing critical lubrication, sealing, and protection against corrosion and wear. Whether in automotive applications, heavy machinery, or industrial settings, selecting the right type of grease can significantly improve equipment performance, reduce maintenance costs, and extend the life of valuable assets. By using high-quality greases tailored to specific needs, businesses can ensure the smooth and efficient operation of their machinery, even in the most demanding environments.